Author: Adam Bergqvist, Sales and Purchasing Manager

Published: October 22, 2025

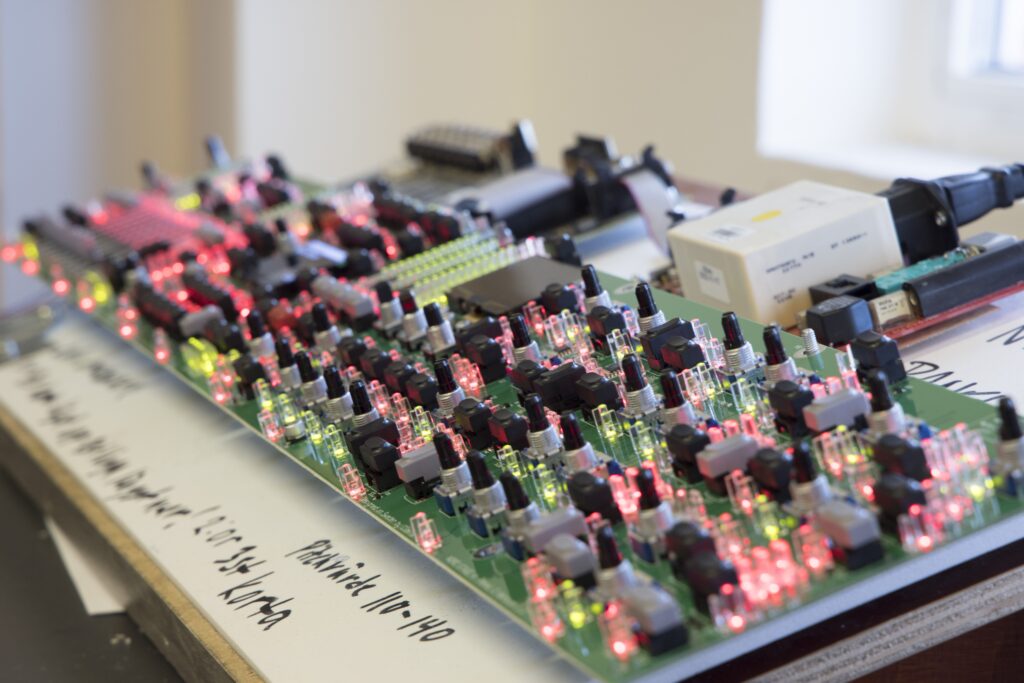

For over 25 years, Mitac has supplied circuit boards to world-leading Clavias Nord Keyboards. What started with a small assignment has today grown into a close and long-term collaboration where trust, flexibility and proximity have been crucial building blocks.

On stage with world stars, in the recording studios of professionals and at home with passionate musicians who seek the best - wherever Nord Keyboards are seen and played, it is clear that Swedish Clavia has managed to create a strong international brand in its niche.

Behind the spotlight and the scenes, however, there is another Swedish player that plays a crucial role in the production chain - Mitac. As specialists in the manufacture of printed circuit boards, they have been developing, producing and supplying the hardware for Nord Keyboard's instruments for over two decades, a contributing factor to the brand's recognized reputation for top quality.

From a small assignment to your own product loops

In the early 90s, Clavia's founder contacted Mitac for a first smaller assignment. Soon the jobs became more numerous, larger and more advanced, and over the years both the relationship and the trust have grown into a close collaboration.

- "We have worked together for so long that it almost feels like we are part of the same organization. The collaboration is based on straightforward communication, mutual respect and a desire to always make the products even better," says Angelina Persson, Operations Manager at Mitac.

Right from the start, Clavia required that their subcontractor should not be more than an hour from their office, something that has subsequently proved to be a crucial success key in the long-term collaboration. The fact that both Clavia and Mitac are based in the Stockholm area has shortened both decision-making paths and cut delivery times, but also created soft added value that appeals to Clavia's end customers.

- Our geographical proximity to Clavia means that we can be flexible, fast and solve things directly, which ultimately contributes to both higher quality and delivery reliability. The fact that Nord Keyboards can write "Handmade in Sweden" on their products also gives them a sense of pride and a strong added value, Angelina explains.

When the details matter

At Mitac, precision and quality are at the heart of everything we do - whatever the customer or product. The circuit boards for Clavia's high-quality audio products are a clear example of the craftsmanship required. Here, each board is tested both visually and automatically before final testing, installation and packaging.

- In our business, there is no room for mistakes. Every component matters, which is why we pay great attention to detail, stable processes and clear quality controls," says Angelina Persson.

Prototyping, testing and continuous development

For each new model from Clavia, an interaction between the engineering and development teams starts. Before volume production begins, the boards are tested, evaluated and adjusted together through a series of prototype runs. New requirements call for new solutions, which has been part of the dynamic that both parties appreciate. For Mitac, this has meant adapting its machinery, processes and personnel to meet the needs.

- This is where our close relationship really makes a difference. We have open and fast communication between our engineers and their developers where we can bounce new ideas, solve issues and adjust in real time - without losing momentum. We like it when we can innovate and solve challenges together," says Angelina.

Delivery precision as a promise

In an industry where products must be shipped to retailers around the world, reliable delivery is often a business-critical issue. For Clavia, it is absolutely central and something Mitac takes very seriously.

- Delays can affect much more than just a delivery. That's why we work hard to always be one step ahead and never lose precision. We will deliver on time and if there is ever a risk of delay, we inform you immediately," says Angelina.

Building the future together

After a quarter of a century together, the relationship between Mitac and Clavia is still evolving. New products, higher demands and technological developments mean that the partnership continues to grow, but with the same core values as from the start: transparency, quality and proximity.

- We feel confident in our role. There is a clarity and trust in the collaboration that makes everything flow naturally even when it gets challenging. At Mitac, we believe in the value of long-term relationships, and this is probably one of our best examples," says Angelina Persson.

Clavia ends on the same note:

- After more than 25 years together, I can only conclude that it has been a good story, where Mitac has proven to be a dream supplier. Their proximity makes our everyday life much easier where we can quickly solve problems, handle prototypes smoothly and ensure quality at every step.

Deliveries are almost always made with impeccable precision and if something is ever in danger of being delayed, we find out before problems arise. In addition, Mitac not only helps us maintain our high quality standards - they challenge us to raise the bar even further," concludes Rasmus Rasmusson, Purchasing Manager at Clavia.

Want to talk PCB manufacturing with precision? Get in touch with me!

Adam Bergqvist

Sales and Purchasing Manager

Want to talk PCB manufacturing with precision? Get in touch with me!

Adam Bergqvist

Sales and Purchasing Manager